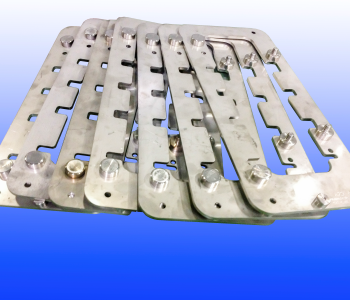

The automotive industry is highly demanding, lead times are short and timescales require robust solutions to be quickly and dependably introduced into service. Seconds count, as in any high volume production environment. Cycle time reduction and manning levels are constantly challenged and poke yoke techniques exercised to allow just in time (JIT) production of high quality products.

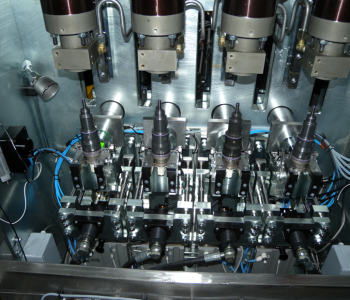

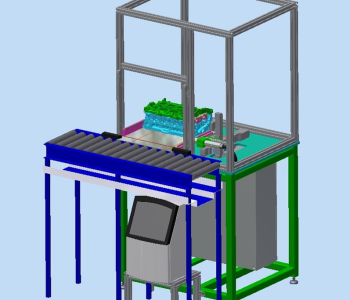

Mecelec Design Ltd has the ability and proven track record to design, build, install and commission complex production assembly machines and analytical test benches to meet the automotive industry’s highest standards and tightest timescales.

Whether it be a fully robotic assembly cell or a simple offline inspection station, our team of highly qualified engineers will provide a cost-effective, dependable, reliable solution for a very wide range of automotive processes.

Recent successes have included a roll-over rig capable of inverting large vehicles to measure fluid loss following crash testing, installation of solar arrays into UV solar loading test chambers, design and installation of an upgraded control system fitted to a vehicle side impact crash test rig.

These are just a few successes. Many other examples of successfully completed projects can be found on the links below: